How Pellet Mills Work

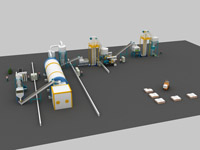

Pellet mills are machines that are used to produce pellets from powdered materials. It is also known as a pellet press. Pellet mills are different from grinding mills. A pellet machine blends small powdered materials to form a large homogeneous mass, while a grinding mill breaks large materials into smaller pieces. These mills are grouped into two broad types: Large-scale mills and Small-scale mills.

|

|

| Large scale pellet mill | Small scale pellet mill |

Large-scale mills are normally ring die pellet mills used to make wood pellets, animal feed and fuel pellets. Small-scale pellet mills are Flat die pellet mills that use a flat die with slots, while a Ring die mill uses radial slots round the die. In Flat die mills, the powder is fed from the top of the die. When the die rotates, the powder is pressed by the roller through the slots and a cutter chops the exposed pellets. In Ring die mills, the powder is fed within the die. Spreaders distribute the powder, as two rollers press the powder through the radial slots. Two cutters cut the exposed pellets.

Small-scale mills work like large-scale mills. Screw press mills and hydraulic press mills are the two common types of small-scale mills. The powder is fed into the die and stored in a shaped pocket. The shape of the final pellet depends on the shaped pocket which held the powder. In screw presses, a platen is fastened to the end of the screw; while in hydraulic presses, the platen is attached to the end of the ram. Heated platen accelerates the production of pellets and betters the structure of the pellet. Water ports are used to cool the heated platens.

Pellet mills help you to produce your animal feed pellets using your own materials. A pellet mill can be operated by one person.

Are you looking for pellet mills? Do you want to……

Biomass energy has sprung up everywhere because ……

Homemade pellet press has now been known to many……